In the world of visual communication, accurate color reproduction is vital—whether in photography, graphic design, packaging, or publishing. One of the most widely used methods for achieving full-color images on physical surfaces is CMYK printing. The acronym stands for Cyan, Magenta, Yellow, and Key (Black), and it refers to the four ink colors used in traditional color printing. To fully understand CMYK printing, it is important to compare it with RGB color, and to understand the fundamental principles of additive and subtractive color models.

What Is CMYK Printing?

CMYK printing is the standard color model used in printing processes, especially for full-color materials like brochures, magazines, books, and packaging. It works by layering the four ink colors (cyan, magenta, yellow, and black) in varying percentages to produce a wide range of colors on white paper.

Each color in CMYK absorbs certain wavelengths of light and reflects others. By overlapping these inks in various proportions, printers can reproduce a broad spectrum of colors. For example, combining cyan and yellow makes green; magenta and yellow make red; cyan and magenta make blue.

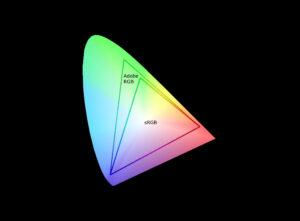

Although CMYK printing can’t reproduce as wide a color gamut as RGB on a screen, it has become the backbone of the printing industry due to its consistency and compatibility with physical materials.

CMYK vs RGB: What’s the Difference?

While CMYK is used for printing, RGB (Red, Green, Blue) is the color model used for digital displays—like computer monitors, smartphones, and TVs. The difference between the two lies not just in the color values but also in how the colors are created.

RGB: The Additive Color Model

RGB uses an additive color model, where colors are created by adding light.

- The base is black, representing the absence of light.

- Red, green, and blue light are added in various combinations and intensities to produce other colors.

- When all three colors are combined at full intensity, the result is white light.

For example:

- Red + Green = Yellow

- Red + Blue = Magenta

- Green + Blue = Cyan

- Red + Green + Blue = White

This model is ideal for screens and other light-emitting sources because it simulates how human eyes perceive color through light wavelengths.

CMYK: The Subtractive Color Model

CMYK, on the other hand, is based on a subtractive color model, where colors are produced by subtracting light using pigment or ink.

- The base is white, representing the natural color of paper reflecting all light.

- As inks are applied, they absorb (subtract) certain wavelengths and reflect others.

- The more colors you mix, the closer you get to black (although in practice, black ink is added separately as “K” to achieve deeper contrast and finer details).

For example:

- Cyan absorbs red, reflects green and blue

- Magenta absorbs green, reflects red and blue

- Yellow absorbs blue, reflects red and green

- Cyan + Magenta + Yellow = a muddy dark brown (not true black, hence the need for a dedicated black ink)

This subtractive approach is effective for printing because it starts from white and removes light through pigments, whereas screens work the opposite way—starting from black and adding light.

Why Is Black (“K”) Included in CMYK?

While theoretically, combining cyan, magenta, and yellow in perfect proportions should produce black, in practice, the result is a murky brown. Therefore, black ink is added in CMYK printing to:

- Produce true black

- Add depth and shadow

- Improve image sharpness

- Reduce ink usage and cost (using black ink is more efficient than mixing all three colors)

The “K” in CMYK stands for “Key” because black is the key plate used for adding detail and contrast in the final printed image.

The Practical Implications

For designers and marketers, understanding the difference between RGB and CMYK is essential. A color that looks vibrant on screen in RGB may appear duller when printed in CMYK because the RGB color gamut is broader. That’s why design files destined for print must be converted to CMYK to ensure accurate color reproduction.

Printers use techniques like halftoning (breaking colors into small dots) and registration marks (for accurate color alignment) to achieve crisp, full-color images.

CMYK printing is a fundamental part of the graphic and printing industries, enabling the production of detailed, full-color images on paper and packaging. Its subtractive color model contrasts with the additive RGB model used for digital screens. While RGB is based on adding light to create color, CMYK works by subtracting light using ink. Understanding this distinction is critical for achieving consistent, accurate color across both digital and physical media. As such, mastering CMYK printing remains a vital skill for anyone involved in design, publishing, and marketing.