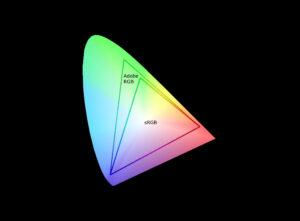

What is spot colour printing? If you’re designing for print—especially logos, packaging, or high-end marketing materials—understanding spot colour printing is essential for achieving colour accuracy and consistency. Unlike standard CMYK printing, spot colour printing uses pre-mixed ink colours to reproduce precise hues, brand colours, and special effects. In this guide, we’ll explain exactly what spot colour printing is, how it works, and when to use it instead of (or alongside) CMYK.

What Is Spot Colour Printing?

Spot colour printing is a printing method where specific colours are applied using pre-mixed inks rather than creating colours through the overlapping of cyan, magenta, yellow, and black (CMYK). Each spot colour is printed using its own dedicated plate and ink, ensuring perfect colour accuracy and consistency across all printed materials.

These inks are often selected from standardised colour systems, the most popular being the Pantone Matching System (PMS). A Pantone spot colour, for example, ensures that a specific shade of blue or red looks exactly the same whether printed today or a year from now, no matter which printer or press is used.

Spot Colour vs CMYK: What’s the Difference?

To understand spot colour printing, it helps to compare it with CMYK process printing:

| Feature | Spot Colour | CMYK (Process Colour) |

|---|---|---|

| Ink Type | Pre-mixed, single ink | Four-colour mix (Cyan, Magenta, Yellow, Black) |

| Colour Accuracy | Extremely high | Can vary based on printer or paper |

| Best For | Brand colours, logos, metallics, neon | Full-colour photos, gradients |

| Cost | Higher for short runs | More economical for complex images |

| Consistency | Identical across jobs | May vary slightly between print runs |

TL;DR:

CMYK printing mixes colours on the page using dots of four inks, while spot colour printing applies a solid, single colour with its own unique ink.

Benefits of Spot Colour Printing

🎯 Unmatched Colour Precision

Spot colours are ideal for reproducing corporate brand colours or logos where exact matches are non-negotiable. Think Coca-Cola red or Tiffany blue.

🧾 Consistent Results

Because spot colours are pre-formulated and not affected by overlapping ink patterns, they deliver consistent output, no matter the printer or run.

🌟 Special Finishes

Spot colour inks allow for metallic, fluorescent, or pastel shades that CMYK simply can’t replicate. Spot varnishes and UV coatings can also be applied using the same concept.

💡 Simplified Printing for Solid Areas

When printing large solid blocks of colour (like a background or icon), spot colours give a cleaner, smoother look without the dot patterns or banding common in CMYK.

When Should You Use Spot Colour Printing?

- Logos and Corporate Branding – to ensure perfect colour match across all materials

- Business Cards and Stationery – when colour consistency is key

- Packaging – especially for high-end or luxury brands

- Posters and Promotional Material – with metallic, neon, or custom colours

- Government or Regulated Industries – where precise reproduction is required by law

If you’re printing a full-colour image like a photo, CMYK is often the better choice. But if you’re producing a design with one to three solid colours, spot printing is usually more cost-effective and reliable.

What Is the Pantone Matching System?

The Pantone Matching System (PMS) is the most widely used spot colour system in the world. It contains thousands of numbered colours, each with a unique formula, so printers can reproduce exact shades. For example, Pantone 186 C is a specific bright red used by many brands.

Pantone colours can be:

- Printed alone as true spot colours, or

- Simulated using Pantone-to-CMYK conversions, although this may lead to less accuracy.

Can Spot Colour and CMYK Be Used Together?

Yes! This is known as “spot + process” printing. It’s common in packaging and premium design work. For instance, a brochure might use CMYK for full-colour photos and a spot colour for a company’s logo to ensure brand consistency. I’ve done this on multiple occasions, it becomes known as a 4 (CMYK) plus 1, 2, 3 or more to make 5, 6, 7 or more colour print.

Spot Colour Printing for Designers: Best Practices

- 🎨 Pick Pantone colours early in the design process

- 📁 Design using vector tools like Adobe Illustrator

- 🖨️ Label spot colours clearly in your print files

- 💬 Communicate with your printer about ink separations and proofs

- 📚 Use Pantone swatch books instead of relying on digital previews (screens vary!)

Is Spot Colour Printing Right for You?

If your brand or project demands precision, consistency, and high visual impact, spot colour printing is likely your best option. It provides greater control over colour than CMYK and opens the door to premium finishes that process printing can’t achieve.

Whether you’re producing branded stationery, luxury packaging, or a design with vibrant neon or metallic hues, spot colour printing delivers results that stand out—literally and visually.